Within the bustling globe of appeal and personal treatment, few industries catch the creative imagination fairly like perfume and cosmetic production. The elaborate process of creating fragrances and cosmetics combines art, science, and a deep understanding of consumer choices. As international need for distinct scents and appeal items continues to rise, the role of ingenious perfume manufacturing, aesthetic production, and well-equipped perfume manufacturing facilities has actually never ever been even more vital. This write-up explores the remarkable landscape of fragrance and cosmetic manufacturing, focusing on the processes included, the innovation made use of, and the trends shaping the market today.

The Significance of Fragrance Production

1. Understanding Scent Composition

The heart of fragrance manufacturing lies in the delicate balance of various aromatic compounds. These can be derived from all-natural sources ( necessary oils, extracts) or synthetically produced in research laboratories. The main categories of scent notes include:

Leading Notes: The first aromas that are perceived upon application, typically citrus or light floral.

Center Notes: Additionally referred to as heart notes, these arise when the top notes fade, often defined by flower, fruity, or flavor scents.

Base Notes: The scents that remain the lengthiest, commonly included heavier components like vanilla, musk, or woodsy aromas.

2. The Production Refine

The fragrance manufacturing procedure usually includes numerous essential actions:

Idea Advancement: This phase involves creative conceptualizing to figure out the style and target market for the fragrance.

Sourcing Ingredients: Makers source high-quality resources, both natural and artificial, to produce the scent. This commonly involves collaborations with neighborhood farmers and providers.

Blending: Specialists in scent formula very carefully mix the selected active ingredients in exact proportions to develop the preferred aroma account, frequently entailing versions and changes.

Aging: Comparable to fine a glass of wine, numerous fragrances take advantage of aging. This permits the fragrance to mature and establish a richer scent over time.

Bottling and Product packaging: Once the desired fragrance is accomplished, it is bottled in aesthetically pleasing containers, usually designed to enhance the overall branding and consumer experience.

The Entire World of Aesthetic Production

1. The Range of Cosmetic Products

Cosmetic manufacturing includes a vast range of items, including skin care, make-up, haircare, and body treatment things. Each classification requires specialized expertise and methods for solution:

Skincare Products: These consist of moisturizers, serums, and cleansers, often concentrating on details skin issues such as hydration, anti-aging, or acne treatment.

Makeup Products: This group includes foundations, lipsticks, eyeshadows, and a lot more, each with distinct formulation challenges to attain wanted color, texture, and long life.

Haircare Solutions: From shampoos to styling products, hair care solutions concentrate on cleaning, nourishing, and protecting hair while providing cosmetic allure.

2. The Manufacturing Process

The actions involved in cosmetic production are rather comparable to those in perfume manufacturing yet customized to fulfill the details demands of each product kind:

R & d: Manufacturers participate in comprehensive research study to develop cutting-edge items that fulfill market needs and regulative criteria.

Formulation: Drug stores and cosmetic scientists create the item formulas, ensuring security, effectiveness, and security via managed research laboratory conditions.

Checking: Products undertake extensive screening for quality assurance, including stability tests, dermatological examinations, and allergic reaction testing to make certain safety and security for consumers.

Manufacturing: Sophisticated equipment is often made use of for massive production, enabling consistent top quality and effectiveness in the manufacturing procedure.

Product packaging: Like fragrances, cosmetics are packaged in visually enticing, practical containers that line up with branding and customer choices.

The Function of Perfume Manufacturing Facilities

1. Innovation and Technology

Fragrance factories are manufacturing centers equipped with advanced technology to support the complex processes associated with creating fragrances and cosmetics. These manufacturing facilities typically include:

Advanced Extraction Techniques: Methods such as vapor purification and cool pushing to get necessary oils and aromatic essences from all-natural resources successfully.

Automated Production Lines: Automation in producing enhances efficiency, decreases human mistake, and permits boosted manufacturing capability.

Quality Control Labs: Fragrance factories commonly maintain strenuous quality control requirements to ensure that each batch meets exacting specifications and customer expectations.

2. Satisfying Consumer Demand

The worldwide demand for special and top quality fragrances and cosmetics needs fragrance factories to be versatile and cutting-edge. Makers should respond to fads, seasonal launches, and transforming consumer choices quickly.

Sustainability Practices: Progressively, customers are attracted to brand names that focus on sustainability. Several fragrance factories apply environmentally friendly techniques, such as sourcing all-natural products sensibly, minimizing waste, and making use of biodegradable product packaging.

Customization: With the introduction of tailored scents and cosmetics, some manufacturing facilities are introducing to provide bespoke production alternatives, enabling consumers to create customized products according to their preferences.

Trends Forming the Industry

1. Natural Components

There is a growing fad towards natural and natural ingredients in both perfume and cosmetic manufacturing. Consumers are ending up being more knowledgeable about the ingredients in their items and are increasingly looking for those that are free from dangerous maklon parfum chemicals. Suppliers are reacting by sourcing sustainable and natural products to satisfy this need.

2. Tidy Appeal Movement

The tidy appeal motion stresses transparency, security, and ethical manufacturing practices. Brand names are concentrating on developing formulas that exclude hazardous active ingredients while making certain high performance. This fad is improving the solution and manufacturing methods of cosmetics.

3. Technological Developments

From AI-driven fragrance advancement to the use of enhanced fact for online try-ons in cosmetics, technological advancements are transforming the method products are established and marketed. Producers who accept these modern technologies are likely to get a one-upmanship.

4. Customization and Personalization

Customers are significantly looking for customized items tailored to their distinct needs and choices. This pattern is pressing suppliers to reconsider traditional product and provide personalized choices, whether in scent or cosmetic formulas.

Final thought

The areas of fragrance production and cosmetic production stand for a fascinating mix of art and science, driven by development and consumer demand. As the market continues to progress, the function of perfume factories in generating top notch, one-of-a-kind products is critical. By welcoming sustainable techniques, progressing innovation, and replying to changing consumer preferences, suppliers can flourish in this competitive landscape.

For anybody interested in the whole world of charm and scent, comprehending the complicated processes associated with crafting fragrances and cosmetics gives beneficial insight into just how these cherished products come to life. As the sector grows and adapts, it will certainly be exciting to see exactly how creative thinking and innovation continue to shape the future of scent and cosmetics.

Neve Campbell Then & Now!

Neve Campbell Then & Now! Lark Voorhies Then & Now!

Lark Voorhies Then & Now! Molly Ringwald Then & Now!

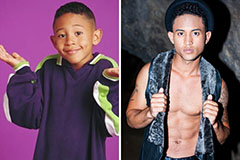

Molly Ringwald Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Elin Nordegren Then & Now!

Elin Nordegren Then & Now!